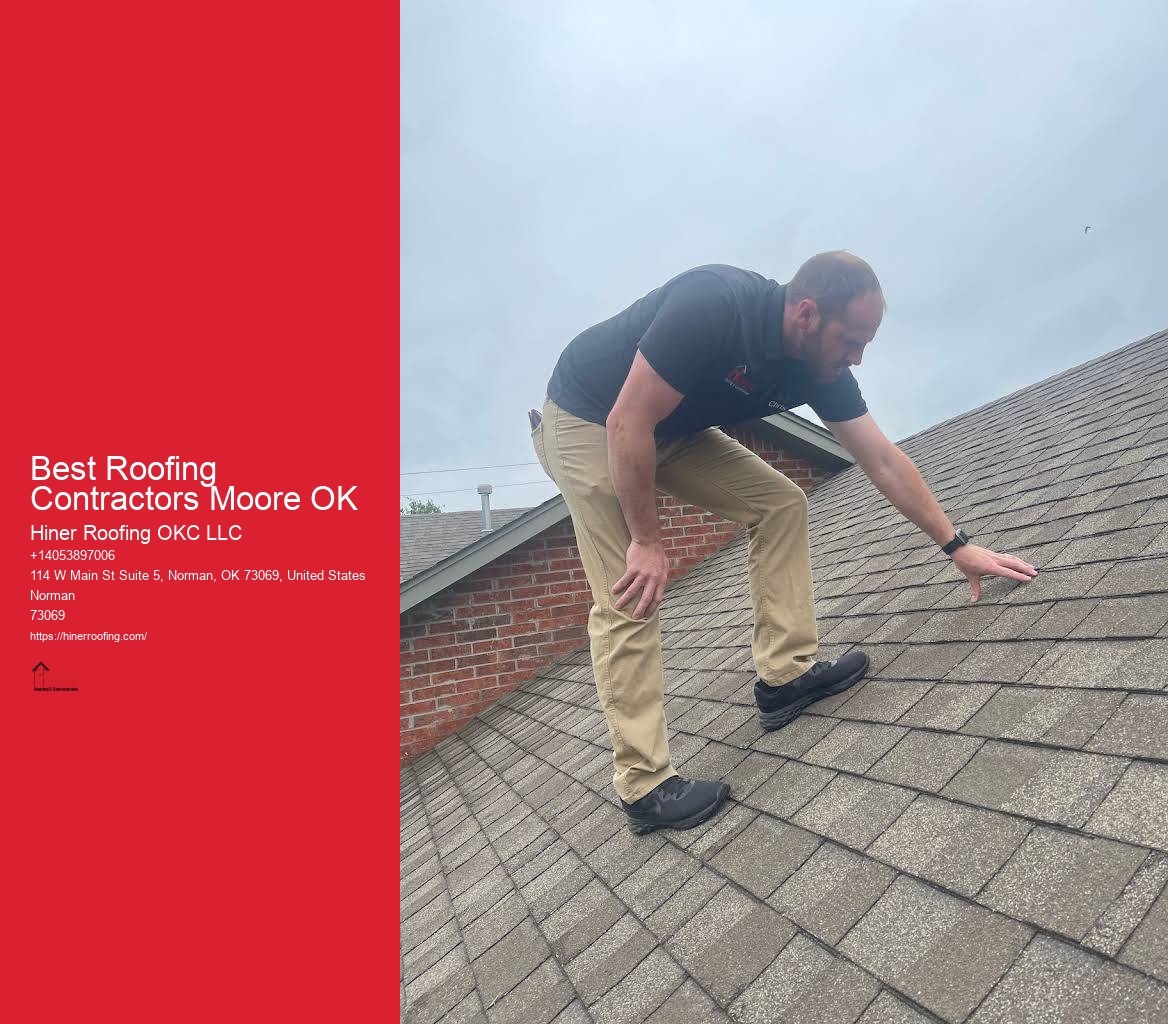

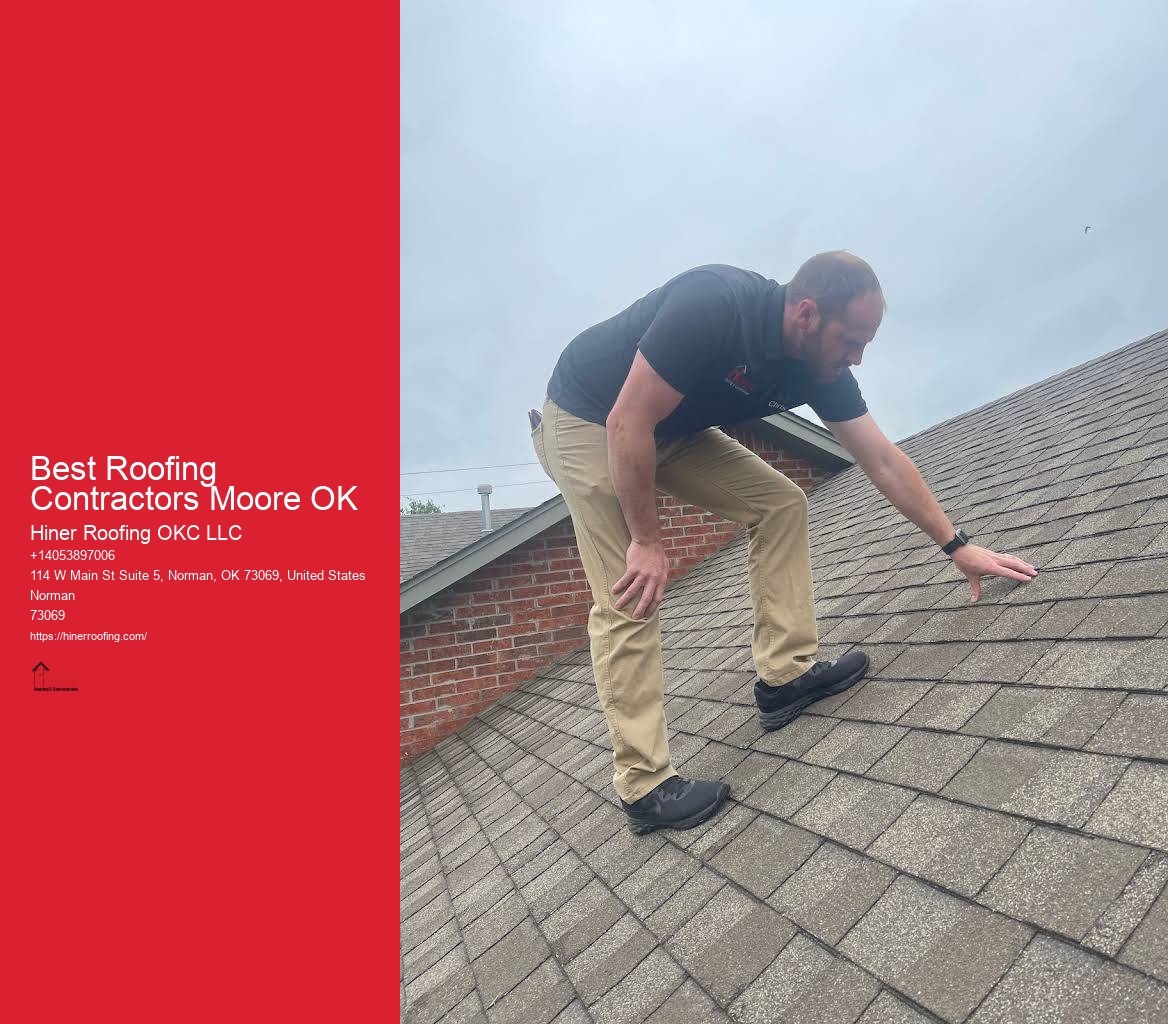

The journey to a new roof begins with a thorough inspection. If you're in a region prone to severe hail, investing in impact-resistant shingles or other roofing materials designed to withstand hail can offer long-term protection and peace of mind. By staying proactive, you can ensure your home remains safe and secure, no matter what Moore's weather throws your way. As you inspect, maintain, and eventually replace your roof, it's crucial to recognize the signs of aging, understand the impact of weather, and appreciate the benefits of timely intervention. Learn more about Best Roofing Contractors Moore OK here These events can wreak havoc on your home's first line of defense: the roof.

They recommend regular maintenance checks to identify and fix minor issues before they escalate. Learn more about Hiner Roofing OKC LLC here. Beyond choosing premium materials, Hiner Roofing OKC employs cutting-edge replacement techniques to ensure your roof isn't only durable but also impeccably installed. But their expertise doesn't stop at repairs. Residential roof repair services A newer, stronger roof can withstand severe weather conditions better than outdated materials, reducing the risk of leaks and damage during the next storm season.

From the initial inspection to the final cleanup, they handle everything with professionalism and care.

It also encompasses the expertise of the installers, the warranty that backs the work, and the peace of mind that comes with knowing your investment is sound. Even small gaps or leaks can lead to higher heating and cooling bills. If you prefer written communication or need to send them detailed information about your roofing needs, emailing them is your best bet. If yours is nearing this age, it's time to start thinking about a replacement. At Hiner Roofing OKC LLC, we've developed a proactive approach to manage these delays effectively, ensuring minimal disruption to your schedule.

While they might seem harmless, they can retain moisture and lead to decay. These small indicators can signal bigger problems down the line. Choosing Hiner Roofing OKC LLC means opting for a service that listens and responds to your needs with precision and care. Building on the foundation of Hiner Roofing OKC's exceptional service, let's explore the high-quality materials that set our roofing solutions apart.

Navigating insurance claims can seem daunting, but it's a crucial step in ensuring your roof repairs are covered. But what sets Hiner Roofing apart in the crowded marketplace, and why should you consider them for your next roof upgrade? We source our materials from industry-leading manufacturers, ensuring that every shingle, tile, or metal panel meets our strict standards for resistance to weather, wear, and tear. TPO roofing systems You might wonder why act quickly? Roofing insurance assistance Moore

Fill it out with your basic information and a brief description of your roofing needs. Communication's the name of the game here. Firstly, we closely monitor weather forecasts and adjust our work plans accordingly. It's the perfect time to ask questions and express any concerns you might have.

| Entity Name | Description | Source |

|---|---|---|

| Oklahoma | A state in the south-central region of the United States, known for its diverse landscapes, Native American heritage, and tornado activity. | Source |

| GAF Materials Corporation | A leading manufacturer of roofing materials in North America, specializing in asphalt shingles and roofing accessories. | Source |

| Roof shingle | A type of roofing material that consists of overlapping elements, commonly made from asphalt, wood, slate, or metal. | Source |

| Caulk | A flexible material used to seal joints or seams in construction and home improvement projects, preventing water and air leakage. | Source |

| Asphalt shingle | A widely used roofing material made from asphalt-saturated fiberglass or organic base, valued for its durability and affordability. | Source |

| Shingles | Overlapping roof or wall coverings made from various materials, providing protection from the elements and enhancing aesthetics. | Source |

| Wood shingle | A roofing material made from split or sawn wood, often used for its natural look and insulating properties. | Source |

| Slate | A fine-grained metamorphic rock used in roofing, flooring, and construction due to its durability and aesthetic appeal. | Source |

| Storm Damage | Damage caused by severe weather events, such as hurricanes, tornadoes, and hailstorms, affecting buildings, infrastructure, and landscapes. | Source |

| Waterproofing | The process of making a structure water-resistant to prevent damage from moisture and leaks, commonly used in roofing and construction. | Source |

| Manufacturing | The industrial production of goods using labor, machinery, tools, and raw materials, essential to economic development. | Source |

| Corrugated galvanised iron | A type of steel sheet coated with zinc for corrosion resistance, commonly used in roofing and construction. | Source |

A major producer of natural gas, oil, and agricultural products, Oklahoma relies on an economic base of aviation, energy, telecommunications, and biotechnology. Oklahoma City and Tulsa serve as Oklahoma's primary economic anchors, with nearly two-thirds of Oklahomans living within their metropolitan statistical areas

Regular inspections are your best bet for catching minor issues before they escalate. This report will include recommendations for any necessary repairs or replacement. Moore roof repair experts Moreover, a high-quality roof upgrade can significantly boost your home's curb appeal, making it stand out in your neighborhood. Next, consider your vehicles. The lifespan of your roof also hinges on the quality of installation, the climate you live in, and how well you keep up with maintenance.

It's not just tornadoes; severe thunderstorms bring with them the risk of heavy rain and hail, which can dent or crack roofing materials, leading to leaks and water damage inside your home.

With Hiner Roofing OKC LLC, the transformation is a testament to quality workmanship and enduring materials, designed to stand the test of time. To extend your roof's lifespan and avoid costly repairs, it's crucial to perform regular preventative maintenance. Whether it's a minor repair or a complete roof replacement, they ensure every job is done right the first time. Remember, a little maintenance goes a long way in keeping your roof in prime condition for years to come. Additionally, we're collaborating with local organizations to provide emergency roofing repairs for public buildings that serve as shelters for those displaced by the storms.

We start by conducting a thorough assessment of the damage, ensuring we understand the full scope of the project. Investing in these can significantly enhance your roof's durability. Before the upgrade, you might've been dealing with leaks, missing shingles, or an outdated look that didn't do your property justice. First off, they conduct regular safety audits and risk assessments to identify and mitigate potential hazards.

Don't forget to inspect your gutters; clogged or damaged gutters can lead to water damage on your roof and the rest of your home. Trimming overhanging branches can prevent them from falling on your roof during severe weather and reduce the accumulation of leaves, which could retain moisture and lead to mold or mildew growth. You can rest assured that with Hiner Roofing OKC LLC, your roof is in expert hands. It's more expensive upfront but lasts longer and offers better protection against the elements.

That's when you need to call in the experts. They'll explain what needs to be fixed, suggest the best materials for the job, and provide a clear, itemized estimate. Fast roof installation Moore Different materials mean different lifespans. It's much cheaper to replace a few shingles now than to deal with water damage to your home's interior later. Shingle replacement Moore

If weather or unexpected issues arise, they're quick to update you and adjust the schedule accordingly. You might be weighing your options and considering the urgency of addressing hail damage, but why should you specifically consider Hiner Roofing? This level of customer service is what sets them apart and why many homeowners in Moore trust them for their roofing projects. With Hiner Roofing, you're not risking your home's safety on subpar solutions.

Choosing the right material involves weighing factors like your budget, the climate in Moore, and your home's architectural style. These are clear indicators that your roof's health is declining. This level of accuracy not only enhances the aesthetic appeal of your roof but also significantly boosts its resistance to high winds and heavy rains. After deciding on Hiner Roofing OKC LLC for your roofing needs, the first step is to schedule an initial consultation to discuss your project in detail. This proactive approach not only extends your roof's lifespan but also maintains its protective capabilities.

You'll notice that every worker is outfitted in the proper gear, ensuring they're safeguarded against common roofing injuries.

When a hailstorm hits, you may not immediately notice the impact on your roof. They didn't just stop at offering immediate repairs; they went a step further by helping you navigate insurance claims, making the process as seamless as possible. Well, minor issues can rapidly evolve into significant concerns, affecting your home's structural stability and potentially leading to costly repairs down the line. You can do this by visiting their website or giving them a call. When you're looking for a reliable team to take care of your roofing needs, they're the ones you turn to.

Installation of the new roofing material follows, adhering to the highest industry standards for durability and weather resistance. We're not just fast; we're thorough, ensuring that your new roof is up to our high standards and yours. You're always in the loop, with clear communication being a cornerstone of their process. It's not just about replacing shingles; it's about ensuring the integrity of your entire roofing system. Roofing warranty services

Imagine selecting a sleek, modern metal roof that not only lasts for decades but also reflects sunlight, reducing your cooling costs. Heavy rain, for instance, can find its way through even the smallest cracks, causing water damage and mold growth in your attic and ceiling. You're not just getting a roofing service; you're securing a peace of mind that your home is in the hands of professionals committed to excellence. Next, the team prepares your property to ensure safety and minimize disruption. Quality roofing Moore

Let's explore the significance of this expansion and how it could enhance the durability and aesthetic appeal of your home.

Roofing can mean:

Roofers working on a bungalow in Brompton, Quebec

|

|

| Occupation | |

|---|---|

|

Occupation type

|

Vocational |

|

Activity sectors

|

Construction |

| Description | |

| Competencies | Heights, patience, steady hand, ability to read plans, physically strong |

|

Education required

|

Apprenticeship |

|

Fields of

employment |

Construction |

|

Related jobs

|

Carpenter, Electrician, Plumber, Welder |

A roofer, roof mechanic, or roofing contractor is a tradesman who specializes in roof construction. Roofers replace, repair, and install the roofs of buildings, using a variety of materials, including shingles, single-ply, bitumen, and metal. Roofing work includes the hoisting, storage, application, and removal of roofing materials and equipment, including related insulation, sheet metal, vapor barrier work, and green technologies rooftop jobs such as vegetative roofs, rainwater harvesting systems, and photovoltaic products, such as solar shingles and solar tiles.[1] [2]

Roofing work can be physically demanding because it may involve heavy lifting, climbing, bending, and kneeling, often in extreme weather conditions.[1] Roofers are also vulnerable to falls from heights due to working at elevated heights. Various protective measures are required in many countries. In the United States these requirement are established by the Occupational Safety and Health Administration (OSHA) to address this concern.[3][4][5] Several resources from occupational health agencies are available on implementing the required and other recommended interventions.[6] [7][8]

According to data from the U.S. Bureau of Labor Statistics (BLS), as of May 2022[update], there were 129,300 individuals working as roofers in the construction industry. Among that population, a majority of roofers (93%; 119,800) were contractors for Foundation, Structure, and Building Exterior projects.[9][10] In terms of jobs outlook, it is predicted that there will only be a 2% increase in job growth from 2022 to 2032 in the United States. Approximately 12,200 openings are expected each year in this decade. Most of the new jobs are likely to be offered to replace roofers who retire or transition out of the trade.[1]

In Australia, this type of carpenter is called a roof carpenter and the term roofer refers to someone who installs the roof cladding (tiles, tin, etc.). The number of roofers in Australia was estimated to be approximately 15,000. New South Wales is the largest province with an 29% market share in the Australian Roofers industry (4,425 companies). Second is Victoria with 3,206 Roofers (21%).[11]

In the United States and Canada, they're often referred to as roofing contractors or roofing professionals. The most common roofing material in the United States is asphalt shingles. In the past, 3-tab shingles were used, but recent trends show "architectural" or "dimensional" shingles becoming very popular.[12]

Depending on the region, other commonly applied roofing materials installed by roofers include concrete tiles, clay tiles, natural or synthetic slate, single-ply (primarily EPDM rubber, PVC, or TPO), rubber shingles (made from recycled tires), glass, metal panels or shingles, wood shakes or shingles, liquid-applied, hot asphalt/rubber, foam, thatch, and solar tiles. "Living roof" systems, or rooftop landscapes, have become increasingly common in recent years in both residential and commercial applications.[13][14]

Roles and responsibilities of roofing professionals include:[1]

Beyond having common duties such as replacing, repairing, or installing roofs for buildings, roofers can also be involved in other tasks, including but is not limited to:

Roofing is one of the most dangerous professions among construction occupations since it involves working at heights and exposes workers to dangerous weather conditions such as extreme heat.[15] In the United States as of 2017, the rate of fatalities from falls among roofers is 36 deaths per 100,000 full-time employees, ten times greater than all construction-related professions combined.[16] In the United States, the fatal injury rate in 2021 was 59.0 per 100,000 full-time roofers, compared to the national average of 3.6 per 100,000 full-time employees.[17] According to the U.S. Bureau of Labor Statistics, roofing has been within the top 5 highest death rates of any profession for over 10 years in a row.[18] For Hispanic roofers, data from 2001–2008 show fatal injuries from falls account for nearly 80% of deaths in this population, the highest cause of death among Hispanics of any construction trade.[19][20]

A major contributing factor to the high fatality rates among roofers in the United States is the nature of the craft which requires roofers to work on elevated, slanted roof surfaces. Findings from qualitative interviews with Michigan roofing contractors also found hand and finger injuries from handling heavy material and back injuries to be some of the more common task/injury combinations.[21]

Ladder falls contribute to the rates of injury and mortality. More than half a million people per year are treated for fall from ladder and over 3000 people die as a result.[22] In 2014 the estimated cost annual cost of ladder injuries, including time away from work, medical, legal, liability expenses was estimated to reach $24 billion.[22] Male, Hispanic, older, self-employed workers and those who work in smaller establishments, and work doing construction, maintenance, and repair experience higher ladder fall injury rates when compared with women and non-Hispanic whites and persons of other races/ethnicities.[23]

Ladders allow for roofers to access upper level work surfaces. For safe use, ladder must be inspected for damage by a competent person and must be used on stable and level surfaces unless they are secured to prevent displacement.[3]

Nearly every industrialized country has established specific safety regulations for work on the roof, ranging from the use of conventional fall protection systems including personal fall arrest systems, guardrail systems, and safety nets.

The European Agency for Safety and Health at Work describes scenarios of risk (fall prevention, falling materials, types of roofs), precautions, training needed and European legislation focused on roof work.[6] European directives set minimum standards for health and safety and are transposed into law in all Member States.

In the United States, OSHA standards require employers to have several means of fall protection available to ensure the safety of workers. In construction, this applies to workers who are exposed to falls of 6 feet or more above lower levels.[3][24] In the United States, regulation of the roofing trade is left up to individual states. Some states leave roofing regulation up to city-level, county-level, and municipal-level jurisdictions. Unlicensed contracting of projects worth over a set threshold may result in stiff fines or even time in prison. In some states, roofers are required to meet insurance and roofing license guidelines. Roofers are also required to display their license number on their marketing material.

Canada's rules are very similar to those from the U.S., and regulatory authority depends on where the business is located and fall under the authority of their local province.

In 2009, in response to high rates of falls in constructions the Japanese Occupational Safety and Health Regulations and Guidelines amended their specific regulations. In 2013 compliance was low and the need for further research and countermeasures for preventing falls and ensuring fall protection from heights was identified.[25]

The United Kingdom has no legislation in place that requires a roofer to have a license to trade, although some do belong to recognized trade organizations.[26]

The purpose of a PFAS is to halt a fall and prevent the worker from making bodily contact with a surface below. The PFAS consists of an anchorage, connectors, body harness and may include a lanyard, deceleration device, lifeline or suitable combination of these.

Beyond these mandatory components of the PFAS, there are also specific fall distances associated with the functioning of the arrest system. Specifically, there is a total fall distance that the PFAS must allow for to assist the worker in avoiding contact with the ground or other surface below. The total fall distance consists of free fall distance, deceleration distance, D-ring shift, Back D-ring height, and Safety margin. In addition to the fall distance requirements for each component of the PFAS, the anchorage of the PFAS must also be able to support a minimum 5,000 pounds per worker.[4]

OSHA regulations have several requirements. The free fall distance, to the distance that the worker drops before the PFAS begins to work and slows the speed of the fall, must be 6 feet or less, nor contact any lower level. The deceleration, the length that the lanyard must stretch in order to arrest the fall must be no more than 3.5 feet.[4] The D-ring shift, the distance that the harness stretches and how far the D-ring itself moves when it encounters the full weight of the worker during a fall, is generally assumed to be 1 foot, depending on the equipment design and the manufacturer of the harness. For the back D-ring height, the distance between the D-ring and the sole of the worker's footwear, employers often use 5 feet as the standard height with the assumption that the worker will be 6 feet in height, but because the D-ring height variability can affect the safety of the system, the back D-ring height must be calculated based on the actual height of the worker. The safety margin, the additional distance that is needed to ensure sufficient clearance between the worker and the surface beneath the worker after a fall occurs, is generally considered to be a minimum of 2 feet.[3]

A fall restraint system is a type of fall protection system where, the goal is to stop workers from reaching the unprotected sides or edges of a working area in which a fall can subsequently occur. This system is useful where a worker may lose their footing near an unprotected edge or begin sliding. In such a case, the fall restraint system will restrain further movement of the worker toward the unprotected side or edge and prevent a serious fall. Although fall restraint systems are not explicitly defined or mentioned in OSHA's fall protection standards for construction,[24][4] they are allowed by OSHA as specified in an OSHA letter of interpretation last updated in 2004.[27] OSHA does not have any specific requirements for fall restraint systems, but recommends that any fall restraint system be capable of withstanding 3,000 pounds or at least twice the maximum predicted force necessary to save the worker from falling to the lower surface.[3] There are no OSHA specifications on the distance from the edge the restraint system must allow for a falling worker, and although a likely very dangerous practice, the OSHA letter of interpretation states that as long as the restraint system prevents the employee from falling off an edge, the employee can be restrained to "within inches of the edge."[27]

Guardrail systems serve as an alternative to PFAS and fall restraint systems by having permanent or temporary guardrails around the perimeter of the roof and any roof openings. OSHA requires the height of the top of the rail to be 39-45 inches above the working surface. Mid-rails must be installed midway between the top of the top rail and the walking/working surface when there is no parapet wall at least 21 inches high. Guardrail systems must be capable of withstanding 200-pounds of force in any outward or downward direction applied within 2 inches of the top edge of the rail.[3][24]

Safety net systems use a tested safety net adjacent to and below the edge of the walking/working surface to catch a worker who may fall off the roof. Safety nets must be installed as close as practicable under the surface where the work is being performed and shall extend outward from the outermost projection of the work surface as follows:[4]

| Vertical distance from working level to horizontal plane of net | Minimum required horizontal distance of outer edge of net from the edge of net from the edge of the working surface |

|---|---|

| Up to 5 feet | 8 feet |

| More than 5 feet up to 10 feet | 10 feet |

| More than 10 feet | 13 feet |

Safety nets must be drop-tested with a 400-pound bag of sand, or submit a certification record prior to its initial use.[4]

Warning lines systems consist of ropes, wires, or chains which are marked every 6 feet with high-visibility material, and must be supported in such a way so that it is between 34 and 39 inches above the walking/working surface.[4] Warning lines are passive systems that allow for a perimeter to be formed around the working area so that workers are aware of dangerous edges. Warning lines are only permitted on roofs with a low slope (having a slope of less than or equal to 4 inches of vertical rise for every 12 inches horizontal length (4:12)).[28] In the context of roofing fall protection, warning line systems may only be used in combination with a guardrail system, a safety net system, a personal fall arrest system, or a safety monitoring system. The warning line system must be erected around all sides of the roof work area.[4]

Safety monitoring systems use safety monitors to monitor the safety of other workers on the roof. Safety monitors must be competent to recognize fall hazards. The safety monitor is tasked to ensure the safety of other workers on the roof and must be able to orally warn an employee when they are in an unsafe situation.[4]

Multi-layered approaches to fall prevention and protection that use the hierarchy of controls can help to prevent fall injuries, incidents, and fatalities in the roofing industry.[7][8] The hierarchy of controls is a way of determining which actions will best control exposures. The hierarchy of controls has five levels of actions to reduce or remove hazards – elimination, substitution, and engineering controls are among the preferred preventive actions based on general effectiveness.

Resources are available to assist with the implementation of fall safety measures in the roofing industry such as fall prevention plans,[23][29] a ladder safety mobile application,[30] infographics and tipsheets,[31] toolbox talks,[32] videos and webinars,[1] and safety leadership training.[2] Many of these resources are available in Spanish and additional languages other than English. The recommended safety measures are described next.

In terms of job outlooks, it is predicted that there will only be an 1% increase in job growth from 2021 to 2032. The job openings (15,000) are expected to replace roofers who will retire or transition out of the trade.[9]

Solar Roof installation is one of the fastest growing trends in the roofing industry due to the nature of solar roofs being environmentally friendly and a worthwhile economic investment. Specifically, solar roofs have been found to allow homeowners to potentially save 40-70% on electric bills depending on the number of tiles installed.[33] The US federal government has also begun incentivizing homeowners to install solar roofs with potential eligibility for 30% tax credit on the cost of a solar system based on federal income taxes.[34]

Across 14 researched markets, roofing contracting companies have reported that they have received more frequent calls regarding potential metal roof installations. For instance, one company used to receive 5-6 calls in total regarding metal installations but recently, they have received 5-6 calls weekly for inquiries regarding metal roof installations.[35]

How Does Hiner Roofing OKC LLC Handle Unexpected Issues (Like Hidden Damage) Discovered During the Roof Replacement?

When Hiner Roofing OKC LLC finds unexpected damage during a roof replacement, they'll assess the situation, inform you about the issue, and discuss options for addressing it, ensuring the project stays on track and within budget.

Are There Any Environmentally Friendly Roofing Options Available Through Hiner Roofing OKC LLC, and How Do They Compare in Terms of Cost and Durability?

You're in luck if you're looking for eco-friendly roofing options. They offer sustainable choices that are cost-effective and durable. Comparing them, you'll find they're a smart investment for both your wallet and the planet.

How Does Hiner Roofing OKC LLC Manage Environmental Sustainability in Its Roofing Practices?

You're probably curious about how Hiner Roofing OKC LLC handles environmental sustainability. They incorporate eco-friendly materials and practices, ensuring their roofing projects not only meet but exceed green building standards. This approach significantly reduces their environmental footprint.